A Primer - Mitsubishi Engine Naming

Mitsubishi Motors uses a simple four-digit naming scheme for its automobile engines:

- The first digit signifies the number of cylinders

- The second is the fuel type; "G" for gasoline, "D" for Diesel, "B" for bio (ethanol)?, "R" for race fuel?

- The third is the engine family (See Below)

- The fourth is the engine model (See Below)

- The first digit is sometimes omitted, shifting the entire scheme by one to make room for another character, such as "T" for turbocharged or "B"for second-generation.

Mitsubishi 4 Cylinder Engine Families

Mitsubishi has developed five families of straight-4 engines:

- 4G1x "Orion" - 1.2L to 1.5L

- 4G3x "Saturn" - 1.2L to 1.8L

- 4G4x "Neptune" - 1.1L - 1.3L

- 4G5x "Astron" - 2.0L to 2.6L <- G54B

- 4G6x "Sirius" - 1.6L - 2.4L <- 4G63

- 4G9x - 1.6L to 2.0L

- 4B1x "GEMA" - 1.8L - 2.4L

All of the above information was gathered using Wikipedia. I have gathered from it and several other sites, the full history of Mitsubishi Engines. This can be found on this thread from the forum. Charlie North has also writen a detailed history which can be found on his site about Classic Colts

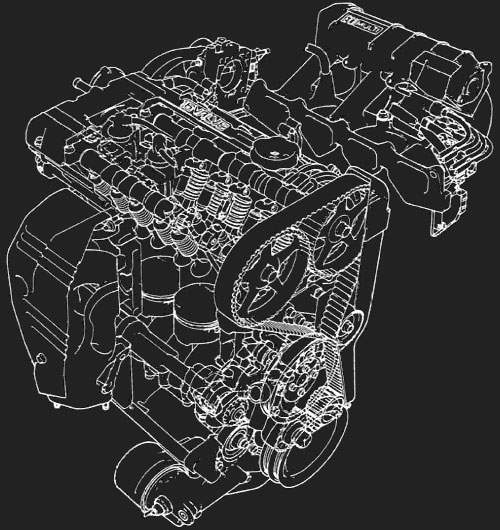

The Sirius Family of Engines (4G6x)

The 4G6x family was released in 1980 as the "Sirius 80" in 4G Galants and 2G Lancers. In 1982 Mitsubishi (MMC) released the "Sirius Dash" in the Starion and Lancer EX turbo. The original 6 bolt (flywheel) engine went through some minor changes throughout the 80s. By 1989 it had a DOHC head on models such as the 1G Eclipse, 6G Galant and 3G Mirage. 6 bolt engines continued until mid 1993.

All 4G6x engines produced after would have 7 bolt cranks. Several changes were made including crank journal width and the oil pump bolt pattern on the front of the block. These changes made swapping cranks, oil pumps and some other parts between the two impossible. Swapping heads and some timing parts was still possible. These engines were used in EvoI-III, 2G Eclipses, 7G Galants, Mighty Max pickups, among others.

Starting with the Evolution IV in 1996, Mitsubishi started phasing out the old 7 bolt engines in favor of a new "backwards" 7 bolt 4G6x engine. To eliminate a shaft in the transmission, they switched the engine from facing to the left side of the car to the right. Engines continued to spin the same clockwise direction as the old motors, but head flow was reversed in order to keep the exhaust at the front of the cars. In addition to the EvoIV-IX, this engine was found in Sonatas, Galants, Outlanders, and some others. The 4G6x is now being phased out to be replaced by the 4B1x engine.

The 4G6x family is very modular and many parts can be interchanged. There are just so many factory configurations, let alone stock ones. Among each engine code there can be MANY variations. Variations include, flywheel bolt pattern (6 or 7), heads, bellhousing bolt pattern, etc.

- 4G61 - 1.6L (Turbo, N/A, High Comp, Small Port DOHC Head)

- 4G62 - 1.8L (N/A DOHC)

- 4G63 - 2.0L (Turbo, N/T, DOHC, SOHC, Wide, Narrow, 6bolt, 7bolt, aka: G63B)

- 4G64 - 2.4L (N/A, SOHC, DOHC, Wide, Narrow, 6bolt, 7bolt, aka: 4GCS, G64B)

- 4G67 - 1.8L (High Comp, Big Port DOHC Head)

- 4G69 - 2.4L (N/T, DOHC, 7 bolt, "backwards")

Mix and Match

Now that we've defined Mitsubishi naming, families and models, we can start to exploit the differences of each engine.

Bottom End

It is possible to swap cranks between blocks of the same generation. These change yield different displacments and rod ratios. Several popular "hybrid" combinations are listed below.

- 2.3L "stroker" motor (2.0L Block, 2.4L crank)

- Larger displacement

- Stock Block / Bore

- Lower Redline Than Stock

- Can use stock 150mm rods / 6mm offset pin stroker pistons

- 2.1L "destroker" motor (2.4L Block, 2.0L crank)

- Slightly Larger displacement

- Much Higher Redline than stock (11,000rpm)

- Need strong 162mm rods / 6mm offset pin stroker pistons

The 4G64 block has a 6mm higher deck height than the 4G63 and a larger bore (87mm). Also, the stock 4G64 crank has a 100mm stroke. The larger displacement will make better low end power and will make power all the way to its suggested 8000rpm redline. Distractors argue that the smaller displacement 4G63 will make more power becuase it is more "square" of an engine (bore = stroke), but this has never been proven to be the case.

If using a SOHC bottom end, main caps are not bridged like on the DOHC motors. It is possible to swap the main caps between bottom ends, but when this is done, the main journals will need to be line bored. Benefits of the semi-bridged mains over the un-briged mains is likely to be insignificant until over 600hp.

There are no piston oil squirters in the SOHC blocks, however, all 4G6x blocks can me made to use them. The holes for the oil squirters can be machined into any 4G6x block. First the pad will need to be machined flat and then a hole will need to be drilled and tapped for the oil squirters. It is important to have a flat surface with a perpendicularly drilled and tapped hole, otherwise the crush washers will leak precious oil pressure from the main gallery. The part numbers for the oil squirters are listed on the part list. Oil squirters are not required when doing a swap. Some argue that with forged pistons, they serve very little purpose at all. Some say they are absolutly required on any turbo engine. Using oil squirters is a judgement call and the costs/benefits of adding them should be considered by the builder.

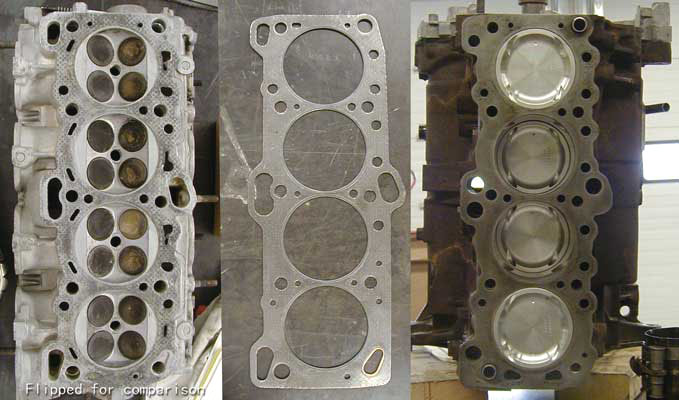

Top End

Among the different bottom end configurations, one can add different heads to mix and match port size and compression ratio. Higher compression ratios would be better for non turbo motors, and lower compression ratios would be better for high boost turbo motors. The bigger you go in regards to port size, the slower the port air speeds and thus the lower the torque. For motors making less than 300hp, smaller ports will make slightly better torque than a larger port motor and will have more material for porting. For high power turbo applications, the big port low compression head is the best bet. Big port heads can be ported as well, but with less material it will be harder to make extreme changes.

To identify which head has which properties, check the casting marks on the backs of the heads. These have some relation to the displacement of the engine the head came on, but there are exceptions. The 2.4L DOHC Galant head was actually a "18" casting. Use the following chart to learn which head has which combination of attributes.

| Compression | |||

| High (43cc) | Low (47cc) | ||

| Port Size | Small | 16 | 20 (2G) |

| Big | 18 | 20 (1G) | |

Another thing that becomes important for us RWD swappers is cam angle sensor (CAS) location. On the 1G heads the CAS is located on the back of the head. With the motor in the stock location, the sensor is tight enough to the firewall that it will be impossible to remove without pulling the motor. With the 95-96 2G head, there is a CAS on the front of the head behind the cam gear. Fitting the crank sensor is a different challenge and has yet to be resolved with an easy fix.

Timing Components

When swapping from a 4G63 to a 4G64 block, one will need to use a different timing belt and different cam gear markings to account for the taller deck height. The timing belt is available from the dealership and some other parts suppliers. Its part number can be found on the part list. Some suggest using 1994 Galant cam gears, but I think this is silly if you already have a 4G63 DOHC set. Simply use a file to remark the gears. Both the Exhaust and Intake gears only need to have the mark advanced half a tooth. Use a paint pen to really make these new marks easy to find.

Sirius motors came with 2 main timing configurations. Dual Over Head Cam (DOHC) and Single Over Head Cam (SOHC). The DOHC head can be found on many different Sirius engines. There are some small differences, but for the most part all are compatible and can be swapped back and forth (even a 1.6L DOHC head onto a 2.4L Turbo). I have gathered info on the SOHC to DOHC conversion in this section.

© 2012 Cybernetics