|

|

|

This motor is totally gay. That's why I'm putting

it in my car. Its out of my '90 GST. I think

the specs are like this:

|

|

Okay... so maybe the specs are exactly like that since

this is straight out of the Factory Service Manual.

If you need a copy I can probably get it to you ('90

talon manual w/ Electrical too). Just hit me up on

AIM or something. As for horsepower the engine comes

from the factory rated at 195HP @ 6000 RPM while

torque peaks at 203ft/lbs @ 3000 RPM. There

is lots of aftermarket support for this motor and there

are motors available everywhere. Hell.. I bought a

whole DSM for $450. I don't doubt that I will see

300+ HP by next summer (if it lasts that long).

Some DSMs can do 450HP on the stock bottom end.

Well over 1000HP with upgraded internals and good

workmanship.

This motor was offered only in FWD as far as I know.

There were some odd usages of it though. Oddly

enough the Starion was the original car to have the

venerable 4G63 2.0. But didn't the Starion only

have the 2.6 G54B? That's only in North America.

In places like Japan, Europe and Australia there was an

optional 2.0L SOHC 12 Valve motor. It was the wide

pattern 4G63. This would be an easy way to upgrade

if you were doing a full rebuild and could locate the

block.

|

|

|

Another RWD "4G63" was the SOHC carbureted G63B found

in the Mitsubishi MightyMax small truck (aka Dodge D50).

This has the "narrow" 4G63 block and therefore has a

narrow bellhousing on the transmission. Speaking

of transmissions and bellhousings... Click

Here |

|

Motor Mounts |

|

People have been really interested in what motor mounts

I used. It's really not that difficult at all.

I used 2 right (narrower) mounts off of a Starion

which I had to re-drill 1 hole. You could also use

MightyMax mounts. Whatever is cheapest.

The real issue for mounting the engine is running

into things. Look here

if you don't believe me that it is tight... too tight.

You can move the motor back 2" from stock, keep it at

the stock spot, or move it forward 2". This is

done by making adapter plates for the motor. The

holes are already in place for mounting the transmission

in any of these 3 positions.

If you want to bang in your firewall you can just

bolt the motor to the mounts and bolt the mounts to the

car. You will also need to worry about

the waterneck and CAS

hitting the firewall and clearing the steering box and

brake booster. You'd almost have to make your own

intake manifold or raise the motor up a few inches and

cut off the back of the manifold.

If you don't want to fuck with your firewall and all

that other stuff you can make adapter plates and extend

the driveshaft 2". The plates are very simple.

There are 2 sets of holes per side. Two of the

holes bolt the plate to the crossmember, 2 of them to

bolt the plates to mounts. The hole that lies

beneath the motor mount will need to be countersunk

enough to not hit the mount. If you countersink it

just the right amount that it slightly touches the mount

this will also lock the bolt in... or you could use

locktight. |

|

|

|

They're neat. Click the photo for a close up.

I made them out of 6061 Aluminum... billet baby! I

used only a table saw, drill press and a file to make

them... I think there was some crazy bit I got from dad

that I used to counter sink a bolt hole. It was

awesomely sharp unlike all my other shitty bits. |

|

Intake Manifold |

|

If you're using the stock intake, this is the place to

look. I can't tell you what to do if you use one

other than stock. Anyways. If you picked to

move the motor forward 2", all you need to do is bolt or

weld a plate over the one end of the manifold.

Then you'll need a flange for the other side. I

actually extended it a little bit. You really just

need to look at it yourself and figure out what is best

for you to do. I tilted mine trying to aim it

towards where I wanted my intercooler pipes would go.

It really doesn't matter. Just be aware that it

needs to be switched :-D. I also had to remove some

junk from the brace under the intake. I did this

with a cold chissel and a grinder. There still may

be some rubbing from the gearbox. I'll make

revisions after some street time. I don't see it

causing any major problems. |

|

|

|

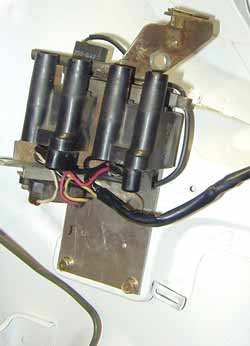

Because you now have this big throttle body on the front

of your intake manifold you will realize that your coil

packs are stuck forever unless you saw your manifold

apart. At least that looks like how it would have

been on my car. So one thing I recommend is moving

the coil packs somewhere else. On the Starion

there just happens to be a convenient place close by

that just seems so right. The plate that the

igniter box was bolted to is an excellent place to mount

the coil packs. I used a thin, long bolts to bolt

the coil packs to an aluminum plate. I also

used rubber hose on the bolts to act as vibration

isolators. TThe wires on the harness will also

reach here without extending anything. You will

need plug wires other than the DSM ones because they are

too short to reach the coil packs. I used my 8mm

Accel wires off of the Starion. |

|

Turbo Rotation |

|

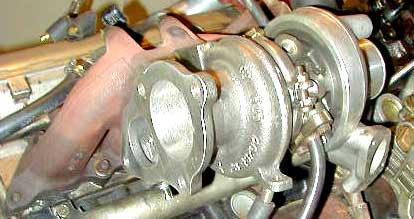

The turbo needs to be turned around 180 degrees so that

the inlet faces the front of the car instead of the

firewall. Alex from Dentsport thinks

otherwise :-D, and it probably made his swap simpler

in the long run (wastegate and oil/water lines).

Rotating the turbine housing in relation to the

compressor housing will make using the stock wastegate

actuator very difficult to use. I ended up using a

35mm external wastegate.

Rotating the housing around also means that you need

to rotate your center cartrige in relation to your

turbine housing. You want the oil drain to face

straight down. This is very simple and only

involves the clamp on the turbo and removing a little

pin.

Depending on how you want to run you

intercooler hoses, you might

want to rotate you compressor housing. To do this

you will need to remove the BIG C-clip with some pliers

and a friend. Then you need to use a small round

file (chainsaw sharpening file) to make a new slot for

the pin on the cartrige. Be sure to mark

everything and not hit the O-ring with the file. |

|

|

|

This is the easy and big stuff. Now on to the

little important and obnoxious things...

the Plumbing. |

|

|